Combigas

Specialist

in Gas Technology

Our customers in healthcare, industry, and laboratories are specialists in their field, delivering unique and high-quality performances. Combigas facilitates these performances by ensuring the quality and safety of gas distribution and gas systems are always guaranteed.

MEDICAL

Medical gases are indispensable in modern healthcare. Your staff working with them are dedicated to delivering the best care for their patients. This involves a lot of considerations.

INDUSTRIAL

Combigas has extensive knowledge and experience in gas distribution for industrial applications.

LABORATORIES

Combigas is your partner for the engineering, design, installation, and maintenance of gas logistics in your laboratory.

WE MAP OUT THE ENTIRE INSTALLATION FOR YOU

Our client base is highly diverse. The installation systems we design and maintain have a wide range of functionalities and meet varying needs and requirements. Therefore, our work is always customized. We map out the entirety of installations within your organization. From there, we collaborate with you on desired solutions, innovations, expansions, and adaptations to all your gas distribution and gas systems.

Our products

From pipe marking stickers to laboratory sampling points, all the products you need for your gas distribution system can be found in our database.

View allCleaned seamless copper tube

In healthcare, laboratories and industry, it is necessary to use materials in gas distribution systems that are guaranteed to be durable and meet high requirements.

Copper has a natural strength. As a result, copper pipes can withstand high working pressure and have a long service life. These properties make the pipes extremely suitable for use in distributing pure gases.

The copper pipes supplied by Combigas are manufactured in accordance with NEN-EN 13348. To prevent contamination during storage and transport, all pipes are always supplied capped.

Material

The quality of the copper used is indicated by Cu-DHP and contains at least 99.9% copper and between 0.015% and 0.040% phosphorus. In addition, a residual carbon content of maximum 0.020 g/m2 is guaranteed. A residual carbon content of maximum 0.010 g/m2 is available on request. Each delivery is provided with a 3.1 certificate in accordance with NEN-EN 10204.

Application

The cleaned seamless copper tube can be used for distributing compressed gases and vacuum within a temperature range of -269°C to 100°C. Other operating temperatures are available on request.

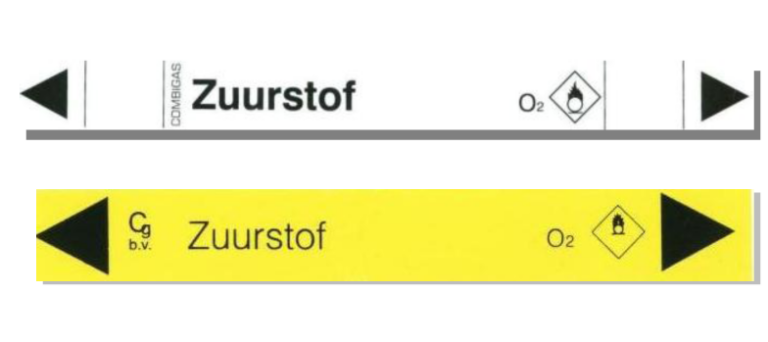

Download het informatiebladPipe markings

To make risks manageable and maintain an overview of building-related gas installations, marking gas pipes is necessary and mandatory under Dutch and European regulations.

The pipe markings must comply with established standards in terms of colour and print. In addition to the colour, the flow direction, name, chemical formula and any hazardous properties of the medium are shown on the marking.

The markings must be applied at least:

- Every 10 metres

- At every branch and at every tap point

- Before and after a wall, bulkhead or wall penetration

Combigas has standardised the most common pipe markings based on current standards.

Material

- Pipe stickers according to NEN 3050: one-sided, self-adhesive standard vinyl. Colour according to NEN3050 with black print.

- Pipe stickers according to NEN-EN-ISO 7396-1: one-sided, self-adhesive standard vinyl. Colour white with colour band according to NEN-EN-ISO 5359 with black print.

Laboratory collection points HiQ

Various gases are used in laboratories, which are often transported to the location where the gases are used by means of a central gas distribution system.

In order to supply the gas correctly to a device or for an application, there are multiple possible points of withdrawal to obtain the desired pressure or flow.

Technical data

- Pin max 40 bar

- Chromed brass. Stainless steel for corrosive gases on request

- Inlet and outlet G ¼” internal thread, including incoming and outgoing stainless steel compression fitting or hose pillar of your choice

- Identification with gas coding

Solenoid valve F420

The solenoid valve F420 from Céodeux-Cryotec is a compact, indirect (servo-controlled) 2/2-way solenoid valve with many possible applications for industrial gas installations.

The F420 is equipped with female BSP threaded connections. Other connections, such as solder connections and clamping ring couplings, are possible. The F420 is supplied in brass as standard.

The valve meets the cleanliness requirements of NEN-EN-ISO 15001:2010 and is therefore suitable for oxygen and can be used in piping systems for medical gases (NEN-EN-ISO 7396-1).

The solenoid valve can be mounted in any position.

Unicontrol collection points

Unicontrol tapping points are extremely suitable for technical industrial gases with a purity of up to 5.0. The tapping point consists of a mounting plate for wall mounting, a ball valve, a pressure regulator equipped with an adjustment gauge according to EN 562 and a hose nozzle for connecting a hose. Multiple versions are also available.

Application

The unicontrol tapping points are extremely suitable for reducing the central line pressure to a user pressure for, among other things, autogenous and welding applications. Due to their large capacity, the unicontrol tapping points are also suitable for other industrial applications, such as blanketing and gassing of products. With an adjustment, they can also be used for the food industry.

Download het informatiebladCylinder central MM70 Acetylene

The MM70 Acetylene cylinder control unit is specially designed to meet the latest requirements of NEN-EN-ISO 14114 to safely reduce acetylene from cylinders to a maximum line pressure of 1.5 bar.

The MM70 series is supplied in a fully complete version, consisting of a mounting plate, quick-release shut-off device, pressure regulator with relief valve and adjustment knob, flame arrester, and supply shut-off valve.

Download het informatieblad